Four Basic Keys to Successful Stone Selection

Four Basic Keys to Successful Stone Selection

Four Basic Keys to Successful Stone Selection : Fitness for Purpose is fundamental to the successful use of stone, but how do we evaluate a stone to ensure its suitability for a particular use or location? In this article we will discuss four basic keys to assist in the selection and specification of the right stone for the job. The keys are relevant to all stone users and specifiers, and they provide a useful starting point for choosing the right stone.

The four keys are:

Stain Resistance

Strength

Resistance to Abrasion

Durability

Stain Resistance

There are three main factors that determine stain resistance, these are:

Water Absorption

Composition

Appearance

The weighting of each of these factors varies depending on the stone type and application.

Water absorption is directly related to stain resistance. Simply put, a higher water absorption capacity allows for a higher ‘stain holding’ capacity. The table below shows the typical absorption capacity for a range of dimension stone types compared to the relevant ASTM specification.

Stone Type

Water Absorption

Typical Range

(weight %)

ASTM

Spec.

Standard

Requirement

(weight %)

Granite

0.8 – 0.01

C615

0.40

Marble

0.8 – 0.04

C503

0.20

Quartz -based

12 – 0.3

C616

8 (Sandstone)

3 (Quartzitic)

Limestone

26 – 0.08

C568

12 (Low Density)

7.5 (Medium Density)

3.0 (High Density)

Slate

6 – 0.3

C629

0.45

A comparison of the typical range with the ASTM specification shows us that a proportion of the dimension stone on the market does not comply with the requirement of the specification. Choosing a stone with a low water absorption is a good start to reducing the risk of staining of the installed material.

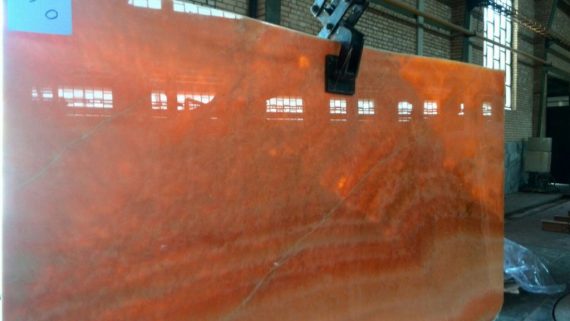

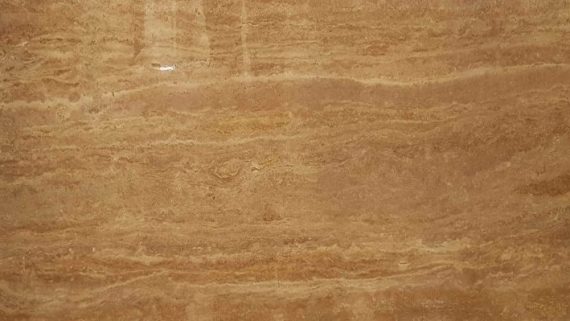

Composition is particularly important considering the current trend towards the use of limestone and travertine. Calcareous stones are susceptible to etching from acidic substances such as wine, soft drinks, urine and even sweaty palms. The use of polished limestone and marble in entertaining areas or any location where acidic spills may occur can lead to conspicuous, etched spots, which can only be removed by mechanical polishing. It is important to note that impregnating sealers will not prevent this etching from occurring. These sealers are designed to restrict the absorption of stains and therefore will not prevent surface etching and subsequent loss of polish. Topical or sacrificial wax coatings should be used to protect acid sensitive materials with a fine finish if they must be used in high risk areas.

The appearance of the stone may prove to be its best asset against staining. Highly figured, dark or variegated stones tend to have a good ‘apparent’ stain resistance, as they have the ability to hide stains. This phenomenon can be compared with the conspicuous appearance of a gravy stain on a plain white shirt compared to a paisley patterned shirt.

Strength

The need for adequate strength may be obvious, but how do we adequately evaluate the strength of stone?

Compressive strength is usually not a problem for dimension stone. However, a major benefit in determining this property, is that it can be performed on small samples such as drill core, making it a useful property for comparing different materials, or determining strength variations within a specific deposit.

The typical range in compressive strength of different stone types is compared below with the ASTM specification.

Stone Type

Typical Compressive Strength

(MPa)

ASTM

Spec.

Standard

Requirement

(MPa)

Granite

300 – 100

C615

131

Marble

150 – 80

C503

52

Quartz-based

120 -10

C616

27.6 (Sandstone)

68.9 (Quartzitic)

Limestone

150 – 4

C568

12 (LD)

28 (MD)

55 (HD)

Slate

200 – 25

C629

–

Flexural strength, is a property that is highly relevant to the adequate performance of a dimension stone. Modern processing facilities can now produce stone in larger and thinner slabs, which can be used to span greater distances with relatively lightweight units. Products such as large flagstones, veneer panels and large bench tops must have an adequate flexural strength to prevent failure.

This property is usually determined by a 4-point loading test where the force is applied to the central half of a specimen. It can also be evaluated by determining the modulus of rupture (MoR), where the specimen is loaded directly at the mid-point of the span.

As some stones experience a reduction in strength of more than 50% after soaking it is important to determine and consider both the dried and soaked strength. If this reduction is not taken into account it could lead to failure of the stone in service.

The typical range of flexural strength (or modulus of rupture) for different stone types are given below. It is essential that these results are considered a minimum whether the material is dried or soaked.

Stone Type

Typical Flexural Strength (MPa)

ASTM

Spec.

Standard

Requirement

(MPa)

Granite

30 – 6

C615

8.3

Marble

22 – 6

C503

7

Quartz-based

15 – 2

C616

2.4 (S) – MoR

6.9 (QS) – MoR

Limestone

21 – 2

C568

2.9 (LD) – MoR

3.4 (MD) – MoR

6.9 (HD) – MoR

Slate

50 – 15

C629

49.6 – MoR

In summary, compressive strength can be determined on relatively small samples and is useful for basic comparison, while determination of flexural strength is most important to ensure adequate performance in service.

How in practice can we predict failure loads? By reorganising the formula provided within AS/NZS 4456.5 (see below), we can determine the theoretical breaking load of an unsupported paver of any size.

Breaking Load = (MoR x 2 x Width x (Thickness)2)/( 3 x Span)

As an example,

A paving unit 600 x 400 x 20mm thick with the material having a modulus of rupture 7 MPa has a theoretical breaking load 1.4 kN (139kg)

If we use a different stone that is twice as strong, we double the breaking load as shown below.

Paving unit 600 x 400 x 20mm thick, modulus of rupture 14 MPa

theoretical breaking load 2.7 kN (275 kg)

But, if we double the thickness of the paver, we increase the breaking load fourfold.

Paving unit 600 x 400 x 40mm thick, modulus of rupture 7 MPa – theoretical breaking load 5.6 kN (555kg).

This basic exercise can be invaluable in determining the minimum flexural strength requirement and/or the optimum unit size.

Resistance to Abrasion

Abrasion resistance is important to maintain the intended surface finish of paving materials. A low resistance to abrasion can result in a significant change in the slip characteristics of the surface by grinding caused by grit and other surface contaminants under foot.

Materials with a textured surface, such as ‘grit-blasted’, are often selected because of their increased slip resistance. In this case, the abrasion resistance of the stone needs to be assessed to determine the effect the anticipated traffic may have on the slip rating.

Within Australia, the abrasion resistance of dimension stone has historically been evaluated using the Taber Abraser method (ASTM C1353). This method determines an Abrasion Index (Ha) – the higher the number the greater the resistance to abrasion. Typical values for a range of dimension stone types are given below along with the standard specifications.

Stone Type

Typical Abrasion Index (Ha)

ASTM

Spec.

Standard

Requirement

Granite

50 – 150

C615

25

Marble

15 – 50

C503

10

Sandstone

4 – 24

C616

2 (S)

8 (QS)

Limestone

<1 – 20

C568

10

Slate

4 – 20

C629

8

A set of recommendations have also been developed within Australia through local observation. These useful guidelines are given below.

Abrasion Index

Appropriate Uses

< 8

Suitable only for domestic or light external traffic situations.

8-12

Suitable only for light commercial or domestic flooring.

12-25

Suitable for general commercial and domestic applications.

>25

Suitable for all uses including high traffic prestige commercial flooring.

When assessing the suitability of the abrasion resistance of a stone, it is important to consider:

Surface Finish – possibility of loss of polish resulting in track marks, changes to slip resistance.Four Basic Keys to Successful Stone Selection

High Traffic Areas – bottle necks in high traffic areas leading to increased wear

Tracking of Particulates – grit brought in from outside sources may abrade polished surfaces

Adjacent Materials – a significant change in abrasion index of adjoining materials may cause lippage with subsequent cleaning difficulties and tripping hazards

Durability

Dimension stone is considered a durable, some may say ‘eternal’ material; this is true as long as the stone is matched with its environment. Decay is normally due to one or all of the following mechanisms:

Salt Attack

Freeze – Thaw Cycling

Dimensional InstabilityFour Basic Keys to Successful Stone Selection

Durability is a complex criteria determined by inherent strength, water absorption and pore space. A higher strength can mitigate the forces applied on the stone by the crystallisation of salts or the expansion of ice crystals. A lower water absorption generally correlates to a greater durability, as it restricts the passage of deleterious solutions, but a larger pore size can assist with durability by reducing the pressure applied by salt or ice crystallization on the walls of the pores.

Within Australia, the durability of a dimension stone is usually determined by evaluating its resistance to salt attack. This test (AS/NZS 4456.10) involves cycles of soaking specimens in a salt solution followed by oven drying. On completion of cycling, the material that is lost from each specimen is weighed and recorded as a proportion of the original weight of the specimen. The test method also gives a useful insight into the mode of decay, whether it may be pitting, cracking delamination or general crumbling.

Although there is not a published specification for evaluating resistance to salt attack, a guideline based on observation under Australian conditions is presented below.

Weight Loss (%)

Grade

Environment Suitability

< 0.1

AA

Aggressive environments, constant wetting and drying and exposure to salt attack

0.1 – 1Four Basic Keys to Successful Stone Selection

A

Exposed to continual wetting and drying or moderate salt attack: Four Basic Keys to Successful Stone Selection

1- 5

B

Exposed to intermittent wetting and drying or moderate level salt attack

6 – 10

C

Exposed to infrequent wetting and drying or low level salt attackFour Basic Keys to Successful Stone Selection

> 10Four Basic Keys to Successful Stone Selection

D

Suitable only for use in sheltered locations free from exposure to salt attack. Additional engineering practices may be required to protect the stone.Four Basic Keys to Successful Stone Selection

Conclusion

The four keys discussed in this article are relevant to all uses of stone; whether the stone is to be used as a kitchen bench top or for cladding a multi-storey building. Although each criterion is important,

the relevance and ‘weighting’ of each key will vary depending on the proposed use and location for the stone.Four Basic Keys to Successful Stone Selection

Gaining information to make an informed choice can often be difficult, especially with the large volume of untraceable and untested material flooding into the country. As an end-user or specifier of stone, it is up to you to demand at least the basic information you require to make an informed choice. Evaluation of basic technical data such as water absorption, strength (compressive and/or flexural), abrasion resistance and durability will give you the ability to choose what best suits your needs.Four Basic Keys to Successful Stone Selection

By: Jim Mann

Comments

Comments are closed.